- Home

- Products

- Compressors

- Reciprocating Air Compressors

- DBK Reciprocating Booster Series

DBK Reciprocating Booster Series

SKU: DBK Reciprocating Booster Series Categories: Compressors, Reciprocating Air Compressors

- General Details

- Specifications

- Product Photos

General Details

DBK Reciprocating Booster Series Air Compressors

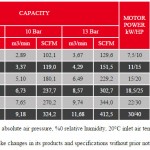

DBK 10 / DBK 15 / DBK 20 / DBK 25 / DBK 30 / DBK 40

DALGAKIRAN, manufactured its first reciprocating air compressor in 1965, promises suitable, trouble-free and high performance for every kind of application with its DBK series reciprocating booster air compressors. Manufacturing and assembly of every single part of these compressors, in which latest engineering softwares are used during design and analysis phases, are realized considering international quality standards.

WHY BOOSTER COMPRESSOR?

Compressed air is a pneumatic energy source which is as important as electricity and hydraulics in production sector. Especially for the production of the pet bottles which the usage of them is getting higher and higher in daily life, high pressure is a must. Besides, the applications such as leak proofing tests of hydraulic and pneumatic devices, specific drive cylinders, presses and fixture apparatus also need high pressure air. Unlike other applications requiring only low pressure air, both low and high pressure levels of air up to 40 bars ought to be used in the facilities for these applications. Therefore, instead of designing whole system considering the high pressure need, increasing the air pressure just at the certain points where high pressure is needed is the most suitable solution.

As a manufacturer having reciprocating booster compressors in its product portfolio which boost the 7-13 bar compressed air taken from rotary screw compressors up to 40 bars, DALGAKIRAN provides the most appropriate solutions with its years of experience and quality policy to pet manufacturers and the enterprises which have to use high pressure air.

LONG LIFECYCLE

Cast-iron crankcase and cylinders, pistons operated at low-speed, corrosion and heat-resistant stainless steel valves, cylinders and bare pumps with cooling fins make DALGAKIRAN DBK series reciprocating booster air compressors durable along their lifecycles.

EASE OF USE

DBK series reciprocating booster air compressors are manufactured to be employed different areas of application without any performance loss. The parts with high performance and quality grades, that are used in manufacturing and assembly of the products designed to make users in every level of experience easily adapt and learn the control, provide long maintenance periods and thus, low operating costs as a result.

WIDESPREAD AFTER-SALES SUPPORT SERVICE

As having operations in more than 100 countries around the globe and possessing more than 150 authorized dealers in Turkey, DALGAKIRAN offers reliable use of the products to its customers with its after-sales support network.

COMPRESSOR BLOCK

• Heavy duty cast-iron crankcases contain oil level indicators properly placed on crankcase, blowdown valve and oil filling/draining plugs.

• Cast-iron cylinders and bare pumps with cooling fins help the system preventing overheat.

• Dynamically balanced and precisely manufactured sphero cast crankshafts and counter weights, which are specially designed in accordance with Lloyd type-approval certification, prolong the lifecycle of the compressor.

• Special design finger-type high capacity and high pressure-resistant inlet-outlet valves made from stainless steel are capable of holding airflow in upper levels as well as operating at high temperatures.

• Compression and oil retaining rings are used for holding the airflow maximized and preventing oil leakages.

MAIN MOTOR AND DRIVE SYSTEM

• High efficiency IE2 class IP55 motors working with 380V/3 phase/50Hz power inlet are used as a standard in DBK series compressors.

• Driving the crankshaft is realized by a belt-pulley mechanism placed between compressor block and main motor and selected considering a suitable transmission ratio.

• Belts are chosen by considering the working life of minimum 25,000 hours

• Special design fan type cast-iron pulleys not only provide airflow with large volumes to cool compressor block but also act as a flywheel to damp the vibrations occurred during operation.

• With easy adjustment of belt tension, continuously efficient operation of the compressor is secured.

• Special loadless operation system lengthens the lifecycle of the main motor and the compressor block.

SAFETY SYSTEMS

• Intake air control system

• High pressure switch

• Manual discharge valve

• Non-return valve

• Belt-pulley guard

• Outlet pressure manometer

STANDARD FEATURES

• Reciprocating compressor block

• 380V/3 phase/50Hz IE2 efficiency class IP55 main motor

• Automatic discharge system for loadless start

• Drive system with belt-pulley mechanism

• Special design fan-type cast-iron pulley

• Long-lasting bearings

• Air-cooled aftercooler

• Air intake filter and silencer for loadless operation

• Lubrication system with whisking rod

• Oil level indicator

• Special discharge system preventing oil leakage from blowdown valve

• Factory-fill oil

OPTIONS

• High pressure air dryer

• CE certified air receiver made from P265GH pressure vessel steel

• Air filtration system with oil trap

• Oil option for food production

• Electronically controlled motor drive system with star-delta connection

• Soft-starter

• IE3 efficiency class main motor

• Power grid options other than 380V/3 phase/50Hz

DBK Reciprocating Booster Series